Last Updated on January 26, 2026

When winter’s icy grip threatens to damage your prized vessel, proper winterization becomes the shield that protects your investment from costly repairs and ensures smooth sailing when spring returns. How to Winterize Your Boat in 5 Steps is a systematic approach that thousands of boat owners rely on to safeguard their watercraft during the harsh winter months, preventing everything from cracked engine blocks to corroded fuel systems.

At Nada Book Info, we understand that your boat represents more than just a recreational vehicle—it’s a gateway to adventure, relaxation, and cherished memories on the water. That’s why learning how to winterize your boat in 5 steps is crucial for maintaining your vessel’s performance, extending its lifespan, and protecting the significant financial investment you’ve made.

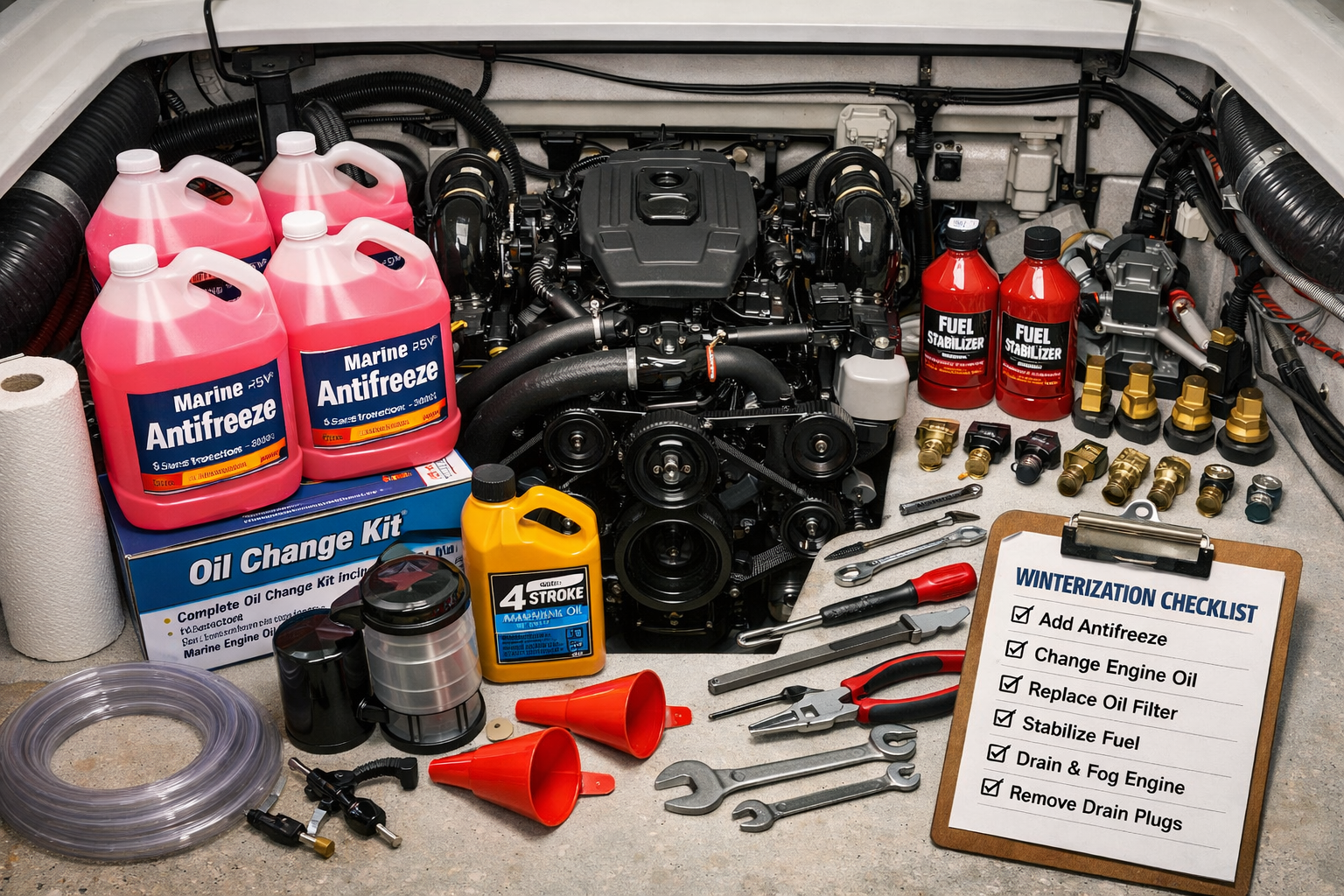

Key Takeaways

• Engine winterization is the most critical step, involving coolant system draining, antifreeze addition, and oil changes to prevent freeze damage

• Fuel system preparation requires adding stabilizer and running the engine to circulate treated fuel throughout the system

• Battery maintenance involves removal, cleaning, and proper storage in a temperature-controlled environment

• Hull and deck protection includes thorough cleaning, waxing, and covering to prevent UV damage and moisture infiltration

• Professional storage or proper DIY storage setup can make the difference between a boat that’s ready for spring and one requiring expensive repairs

Why Winterizing Your Boat is Essential

Winter weather poses serious threats to marine vessels, with freezing temperatures capable of causing thousands of dollars in damage within a single cold snap. Proper boat winterization protects against multiple hazards that can devastate unprepared watercraft during the off-season.

The Science Behind Freeze Damage

Water expands approximately 9% when it freezes [1], creating tremendous pressure that can crack engine blocks, split cooling system components, and rupture plumbing lines. This expansion force generates pressures exceeding 25,000 pounds per square inch, easily overwhelming the structural integrity of marine engines and systems.

Financial Impact of Poor Winterization

According to marine insurance data, inadequate winterization accounts for over 40% of winter-related boat damage claims [2]. The average cost of freeze-related engine repairs ranges from $3,000 to $15,000, while a comprehensive winterization service typically costs between $300 to $800—making proper preparation a wise investment.

Common Winter Damage Scenarios

❄️ Engine Block Cracking: Residual water in cooling passages freezes and expands

🔋 Battery Failure: Cold temperatures reduce capacity and can cause permanent damage

⛽ Fuel System Problems: Untreated fuel degrades and can clog injectors

🚤 Hull Damage: Ice formation and UV exposure during storage

🔧 Corrosion Issues: Moisture and salt buildup accelerate metal degradation

Understanding Your Boat’s Winterization Needs

Before diving into how to winterize your boat in 5 steps, it’s essential to understand that different boat types, engines, and storage situations require tailored approaches to winter preparation.

Boat Type Considerations

Inboard Engines require the most comprehensive winterization due to complex cooling systems that retain significant amounts of water. These engines need complete coolant system draining and antifreeze circulation to prevent freeze damage.

Outboard Motors are generally easier to winterize since they can be tilted to drain water naturally. However, they still require fuel treatment, oil changes, and proper storage preparation.

Sterndrive/Inboard-Outboard systems combine elements of both engine types, requiring attention to both the inboard engine components and the outdrive unit’s cooling passages.

Storage Environment Factors

🏠 Indoor Heated Storage: Provides maximum protection but still requires fuel treatment and basic maintenance

🏢 Indoor Unheated Storage: Requires full winterization but offers protection from weather elements

🌨️ Outdoor Storage: Demands comprehensive winterization plus additional protection from UV rays and precipitation

💧 In-Water Storage: Requires specialized preparation including through-hull protection and continuous monitoring

Regional Climate Considerations

Northern Climates (zones with temperatures below 32°F) require complete freeze protection for all water-containing systems. Southern Climates may focus more on fuel stabilization and corrosion prevention rather than freeze protection.

Step 1: Engine and Cooling System Winterization

The engine represents the heart of your vessel and requires the most attention when learning how to winterize your boat in 5 steps. Proper engine winterization prevents costly freeze damage while ensuring reliable performance when boating season returns.

Cooling System Preparation

Drain All Water: Begin by removing all drain plugs from the engine block, manifolds, and heat exchangers. Allow gravity to remove as much water as possible, but remember that some water will always remain in low points and passages.

Flush with Antifreeze: Use marine-grade antifreeze (propylene glycol-based) rather than automotive antifreeze, which is toxic and harmful to marine environments. Connect a flush kit or use the raw water intake to circulate antifreeze throughout the cooling system.

Antifreeze Circulation Process:

- Start with 2-3 gallons of marine antifreeze in a container

- Connect pickup hose to antifreeze container

- Start engine and run until pink antifreeze flows from all outlets

- Continue running for 2-3 minutes after consistent color appears

- Shut down engine and disconnect flush system

Engine Oil and Filter Service

Oil Change Importance: Used oil contains acids and contaminants that can cause corrosion during storage. Fresh oil provides better protection and ensures clean lubrication when the engine is restarted.

Filter Replacement: Install a new oil filter along with fresh oil. The filter removes contaminants and ensures clean oil circulation throughout the engine during storage.

Oil Change Procedure:

- Warm engine to operating temperature (warm oil drains more completely)

- Remove drain plug and allow complete drainage

- Replace drain plug with new gasket if needed

- Install new oil filter with thin coat of oil on gasket

- Add manufacturer-specified oil quantity and viscosity

Fuel System Treatment

Fuel Stabilizer Addition: Add marine fuel stabilizer to prevent fuel degradation, gum formation, and water absorption. Use manufacturer-recommended ratios, typically 1 ounce per gallon of fuel.

Complete Fuel System Circulation: After adding stabilizer, run the engine for 10-15 minutes to circulate treated fuel throughout the entire system, including carburetors, fuel injectors, and fuel lines.

Fuel Tank Considerations: Fill the tank to 90% capacity to minimize air space and condensation formation, but leave room for fuel expansion.

Step 2: Fuel System and Engine Components

Continuing with how to winterize your boat in 5 steps, the fuel system requires specific attention to prevent degradation and ensure reliable spring startup. Untreated fuel can cause significant problems ranging from clogged injectors to complete engine failure.

Advanced Fuel Treatment Strategies

Fuel Quality Assessment: Before adding stabilizer, check fuel quality for water contamination, debris, or signs of degradation. Poor-quality fuel should be removed and replaced rather than treated.

Biocide Treatment: In areas with high humidity or known fuel contamination issues, consider adding biocide to prevent microbial growth during storage. Diesel engines are particularly susceptible to fuel contamination.

Fuel Line and Filter Maintenance:

- Replace fuel filters to ensure clean fuel flow

- Inspect fuel lines for cracks, softness, or deterioration

- Check fuel tank vents for proper operation

- Examine fuel pumps for leaks or damage

Carburetor and Fuel Injection Winterization

Carbureted Engines:

- Drain carburetor bowls completely or run engine until fuel is consumed

- Spray fogging oil into carburetor throat while engine runs

- Remove and clean carburetor if heavily contaminated

Fuel Injected Engines:

- Ensure stabilized fuel reaches all injectors

- Consider professional fuel injection cleaning if performance issues exist

- Check fuel rail pressure and injector operation

Engine Fogging Process

Fogging Oil Application: Spray fogging oil into engine cylinders through spark plug holes or air intake to coat internal components and prevent corrosion.

Two-Stroke Engines: Add fogging oil to fuel mixture or spray directly into carburetors while running

Four-Stroke Engines: Remove spark plugs and spray fogging oil directly into cylinders, then turn engine over manually to distribute oil

Step 3: Battery Care and Electrical System Maintenance

Battery maintenance represents a crucial component when mastering how to winterize your boat in 5 steps. Cold weather dramatically affects battery performance, and improper storage can result in permanent damage or significantly reduced lifespan.

Battery Removal and Cleaning

Safe Removal Process:

- Disconnect negative terminal first, then positive

- Remove hold-down brackets and carefully lift battery

- Clean terminals with baking soda solution to neutralize acid

- Inspect battery case for cracks, bulging, or damage

- Check electrolyte levels in serviceable batteries

Terminal Maintenance: Clean battery terminals with a wire brush and apply dielectric grease or petroleum jelly to prevent corrosion during storage.

Battery Storage Best Practices

Temperature Control: Store batteries in temperatures between 32°F and 80°F. Extreme cold reduces capacity while excessive heat accelerates self-discharge and shortens lifespan.

Charge Maintenance: Fully charge batteries before storage and maintain charge with a quality battery tender or trickle charger designed for marine applications.

Storage Location Requirements:

- Dry, well-ventilated area

- Away from heat sources and direct sunlight

- On wooden blocks or battery stands (not concrete)

- Accessible for periodic charge monitoring

Electrical System Protection

Circuit Inspection: Check all electrical connections for corrosion, loose wires, or damaged insulation. Marine environments accelerate electrical system degradation.

Electronics Protection: Remove portable electronics or ensure they’re stored in moisture-free environments. Consider using desiccant packs in enclosed electrical compartments.

Corrosion Prevention:

- Spray electrical connections with corrosion inhibitor

- Ensure all through-hull fittings are properly sealed

- Check bilge pump operation and clean if necessary

Step 4: Hull, Deck, and Interior Protection

The fourth step in how to winterize your boat in 5 steps focuses on protecting your boat’s exterior and interior surfaces from winter weather, UV damage, and moisture infiltration that can cause long-term deterioration.

Hull Cleaning and Protection

Thorough Hull Washing: Remove all salt, algae, and marine growth using appropriate cleaners. Salt residue accelerates corrosion and can cause permanent staining if left untreated during storage.

Hull Inspection Process:

- Check for scratches, gouges, or gel coat damage

- Inspect through-hull fittings for proper sealing

- Examine prop and running gear for damage

- Look for signs of osmotic blistering in fiberglass hulls

Protective Waxing: Apply high-quality marine wax to gel coat surfaces. Wax provides UV protection and makes spring cleaning easier by preventing dirt and stains from adhering to surfaces.

Deck and Hardware Maintenance

Deck Cleaning: Use appropriate cleaners for deck material (fiberglass, aluminum, wood) and remove all dirt, salt, and stains. Pay special attention to non-skid surfaces where dirt accumulates.

Hardware Protection:

- Lubricate winches, hinges, and moving parts

- Apply corrosion inhibitor to stainless steel fittings

- Check and tighten all fasteners

- Inspect canvas and upholstery for damage

Interior Winterization

Moisture Control: Remove all fabric items, cushions, and anything that can retain moisture. Use moisture absorbers or dehumidifiers in closed spaces to prevent mold and mildew.

Plumbing System Winterization:

- Drain all water tanks and lines

- Add antifreeze to toilet and holding tank systems

- Winterize freshwater systems with marine antifreeze

- Ensure all through-hull valves are properly positioned

Ventilation Setup: Provide adequate ventilation to prevent condensation buildup while keeping precipitation out. Slightly open hatches with covers or install ventilation fans.

Canvas and Cover Preparation

Canvas Cleaning: Clean all canvas thoroughly and ensure it’s completely dry before storage. Mold and mildew can permanently damage canvas materials.

Cover Installation: Use properly fitted covers that allow air circulation while keeping moisture out. Avoid plastic tarps that can trap moisture and cause more damage than protection.

Step 5: Proper Storage and Final Preparations

The final step in how to winterize your boat in 5 steps involves selecting appropriate storage methods and completing final preparations that ensure your boat remains protected throughout the winter months.

Storage Location Selection

Indoor Heated Storage: Provides maximum protection and may reduce winterization requirements, but represents the most expensive option. Ideal for high-value vessels or areas with extreme weather conditions.

Indoor Unheated Storage: Offers excellent protection from weather while requiring full winterization. Provides good value for money and protection from UV damage and precipitation.

Outdoor Storage Considerations:

- Choose level, well-drained locations

- Ensure adequate support for hull and trailer

- Provide protection from prevailing winds

- Consider security and accessibility factors

Trailer and Support System Preparation

Trailer Maintenance: Service trailer bearings, check tire pressure, and inspect lights and wiring. Properly maintained trailers ensure safe transport and prevent damage during storage.

Hull Support: Ensure proper support distribution to prevent hull distortion. Use adjustable stands or blocks at manufacturer-recommended points.

Weight Distribution: Remove heavy items from boat to reduce stress on hull and support systems. Store gear in dry, secure locations.

Final System Checks

Documentation: Create a winterization checklist noting all completed tasks, fluid levels, and any issues discovered during the process. This documentation proves valuable for spring commissioning.

Security Measures: Remove valuable items, lock all compartments, and consider alarm systems for outdoor storage. Theft prevention protects both equipment and insurance coverage.

Insurance Considerations: Notify insurance company of storage location and winterization status. Some policies require specific winterization procedures or storage conditions.

Professional vs. DIY Winterization

Understanding how to winterize your boat in 5 steps includes evaluating whether to tackle the project yourself or hire professional services. Each approach offers distinct advantages depending on your skill level, available time, and boat complexity.

DIY Winterization Advantages

Cost Savings: Performing winterization yourself can save $300-800 in labor costs while providing valuable learning experience about your boat’s systems.

Timing Flexibility: Complete winterization on your schedule rather than waiting for service appointments during busy fall periods.

System Familiarity: Hands-on winterization increases understanding of boat systems and helps identify potential problems before they become serious issues.

Professional Service Benefits

Expertise and Experience: Professional technicians understand nuances of different engine types and can identify problems that inexperienced owners might miss.

Warranty Protection: Professional winterization often includes service warranties and insurance coverage for any damage caused by improper procedures.

Comprehensive Service: Marine service centers can address multiple systems simultaneously and often provide storage services as package deals.

Hybrid Approach Considerations

Many boat owners choose a hybrid approach, performing basic tasks like cleaning and battery removal while leaving complex engine winterization to professionals. This strategy balances cost savings with professional expertise for critical systems.

Common Winterization Mistakes to Avoid

Even when following how to winterize your boat in 5 steps, certain mistakes can compromise winter protection and lead to expensive spring repairs.

Engine-Related Errors

❌ Incomplete Water Removal: Failing to remove all water from cooling systems remains the most common and costly mistake

❌ Wrong Antifreeze Type: Using automotive antifreeze instead of marine-grade products

❌ Insufficient Antifreeze Circulation: Not running antifreeze through entire cooling system

❌ Skipping Oil Changes: Leaving contaminated oil in engine during storage

Fuel System Mistakes

❌ Inadequate Stabilizer: Using insufficient fuel stabilizer or failing to circulate treated fuel

❌ Fuel Tank Issues: Leaving tank nearly empty (promotes condensation) or completely full (no expansion room)

❌ Ignoring Fuel Quality: Treating poor-quality fuel instead of replacing it

Storage and Preparation Errors

❌ Poor Ventilation: Creating moisture traps with improper covering or ventilation

❌ Inadequate Support: Improper hull support leading to stress cracks or distortion

❌ Security Oversights: Leaving valuable items in boat or failing to secure storage area

Regional Winterization Considerations

How to winterize your boat in 5 steps varies based on geographic location and climate conditions. Understanding regional requirements ensures appropriate protection levels.

Northern Climate Winterization

Extreme Cold Protection: Areas with temperatures below 0°F require additional antifreeze concentration and extra attention to water removal from all systems.

Extended Storage Periods: Longer winter seasons demand more comprehensive fuel treatment and battery maintenance programs.

Ice Damage Prevention: Boats stored in water require specialized equipment like bubblers or de-icers to prevent ice damage.

Southern Climate Adaptations

UV Protection Focus: Intense sunlight requires extra attention to canvas, upholstery, and gel coat protection even during winter months.

Humidity Control: High humidity levels increase mold and mildew risks, requiring enhanced ventilation and moisture control measures.

Reduced Freeze Protection: Milder climates may allow simplified winterization focusing on fuel treatment and basic maintenance rather than freeze protection.

Coastal vs. Inland Considerations

Salt Water Exposure: Coastal boats require more aggressive corrosion prevention and thorough salt removal during winterization.

Freshwater Storage: Inland boats may have different through-hull requirements and reduced corrosion concerns but still need comprehensive winterization.

Spring Commissioning Preparation

Proper winterization sets the stage for efficient spring commissioning. Understanding how to winterize your boat in 5 steps includes planning for spring reactivation.

Documentation and Record Keeping

Winterization Records: Maintain detailed records of all winterization procedures, fluid changes, and system conditions for reference during spring commissioning.

Problem Identification: Note any issues discovered during winterization for attention during spring preparation.

Service Schedules: Plan spring maintenance based on winterization findings and manufacturer recommendations.

Spring Startup Considerations

Reverse Winterization: Systematically reverse winterization procedures, checking each system before operation.

Fluid Changes: Some fluids changed during winterization may need replacement again in spring, particularly if storage period was extended.

System Testing: Test all systems thoroughly before first use, including safety equipment and emergency systems.

Cost-Benefit Analysis of Proper Winterization

Understanding the financial aspects of how to winterize your boat in 5 steps helps justify the investment in proper winter preparation.

Winterization Costs

| Service Category | DIY Cost | Professional Cost |

|---|---|---|

| Engine Winterization | $50-100 | $200-400 |

| Fuel Treatment | $20-40 | $50-100 |

| Battery Service | $10-30 | $50-100 |

| Cleaning/Waxing | $50-100 | $150-300 |

| Storage Preparation | $30-50 | $100-200 |

| Total Range | $160-320 | $550-1,100 |

Potential Damage Costs

| Damage Type | Repair Cost Range |

|---|---|

| Cracked Engine Block | $5,000-15,000 |

| Frozen Cooling System | $1,000-3,000 |

| Fuel System Damage | $500-2,000 |

| Battery Replacement | $200-800 |

| Corrosion Repair | $500-5,000 |

The return on investment for proper winterization typically exceeds 10:1, making it one of the most cost-effective boat maintenance activities.

Advanced Winterization Techniques

For boat owners seeking to master how to winterize your boat in 5 steps at an expert level, advanced techniques provide additional protection and convenience.

Engine Block Heaters

Installation Benefits: Engine block heaters maintain minimum temperatures in extremely cold climates, reducing winterization requirements while ensuring easier spring startup.

Types Available:

- Freeze plug heaters (most common)

- Oil pan heaters

- Circulating coolant heaters

- Battery warmers

Fuel Polishing Systems

Fuel Quality Maintenance: Fuel polishing systems continuously filter and circulate fuel during storage, preventing degradation and water accumulation.

System Components:

- Filtration units with water separation

- Circulation pumps with timers

- Biocide injection systems

- Fuel quality monitoring

Automated Monitoring Systems

Remote Monitoring: Advanced systems provide real-time monitoring of temperature, humidity, and security status via smartphone apps.

Alert Systems: Automated alerts notify owners of temperature changes, intrusion, or system failures requiring immediate attention.

Environmental Considerations

Responsible winterization practices align with environmental stewardship while following how to winterize your boat in 5 Steps guidelines.

Eco-Friendly Products

Biodegradable Antifreeze: Propylene glycol-based antifreeze breaks down naturally and poses minimal environmental risk compared to ethylene glycol products.

Non-Toxic Cleaners: Choose biodegradable cleaning products that won’t harm marine environments when boats return to water.

Proper Disposal: Dispose of used oils, filters, and antifreeze at certified recycling centers rather than dumping in storm drains or soil.

Sustainable Practices

Waste Reduction: Minimize packaging waste by purchasing products in bulk or concentrates when possible.

Energy Efficiency: Use energy-efficient battery maintainers and heating systems to reduce environmental impact.

Water Conservation: Employ efficient washing techniques that minimize water usage while maintaining cleanliness standards.

Conclusion

Mastering how to winterize your boat in 5 steps represents one of the most important skills every boat owner should develop. This comprehensive process—encompassing engine and cooling system preparation, fuel system treatment, battery maintenance, hull protection, and proper storage—forms the foundation of responsible boat ownership and long-term vessel preservation.

The investment in proper winterization, whether through DIY efforts or professional services, pays substantial dividends in prevented damage, extended equipment life, and reliable spring performance. By following these systematic steps and avoiding common mistakes, boat owners protect their significant investment while ensuring countless future seasons of safe, enjoyable boating.

Remember that winterization requirements vary based on climate, storage conditions, and boat type. Adapt these guidelines to your specific situation while maintaining focus on the core principles: remove water from all systems, treat fuel properly, protect batteries, clean and protect surfaces, and ensure secure storage.

Take action today by creating your personalized winterization checklist, gathering necessary supplies, and scheduling professional services if needed. Your future self will appreciate the effort when spring arrives and your boat starts reliably, runs smoothly, and shows no signs of winter damage.

For more expert guidance on boat maintenance, engine care, and seasonal preparation, continue following Nada Book Info’s comprehensive resources for marine enthusiasts. Proper winterization is just one aspect of responsible boat ownership that ensures years of reliable service and memorable experiences on the water.

References

[1] National Institute of Standards and Technology. “Properties of Water and Steam.” NIST Chemistry WebBook, 2026.

[2] BoatUS Marine Insurance. “Annual Boat Insurance Claim Report.” BoatUS Foundation, 2025.